Cable Accessories LV to EHV

Standards governing Cable Accessories

Designed for reliability and service life even in environmental extremes, Raychem comprehensive range of cable accessories help maintain service reliability in both overhead and underground installations. That’s why the most innovative utilities and industries around the world, including underground, substations, offshore, nuclear and renewable have relied on Raychem power cable accessories for more than 60 years. Our history of innovation, legacy of reliable products and decades of experience enable powerful connections for electrical networks and the people who make them.

- Power Cable Joints & Terminations up to 245kV

- Switchgear & Motor Connection System

- Link Boxes & Sheath Voltage Limiters

- Cable End Caps

- Cable Entry Sealing System

- Cable Sealing Glands

- Cable Repair Kits, Ties and Cleats

- Installation & Spiking Tools

Range of Cable Accessories

Low Voltage Joints & Terminations

1.1 kV – Heat Shrink & Cold Applied

- Heat Shrink & Cold Applied Technology

- Quick and easy Installation

- Solutions for all types of cable and constructions

- Hot melt adhesive coated cable breakout and sealing sleeves

- Crimping Less Connector

1.1kV Cold Applied Rayvolve Roll-on Joint. Rayvolve RVS jointing is the “roll-on” way to insulate and seal cable connections up to 1.1kV. The gripping force, of a specially formulated EPDM elastomer, combined with high-performance sealant forms a reliable and water-resistant insulating sleeve. The product is UL listed and CSA certified for direct burial applications.

1.1kV Cold Applied Rayvolve Roll-on Joint. Rayvolve RVS jointing is the “roll-on” way to insulate and seal cable connections up to 1.1kV. The gripping force, of a specially formulated EPDM elastomer, combined with high-performance sealant forms a reliable and water-resistant insulating sleeve. The product is UL listed and CSA certified for direct burial applications.

1.1kV Heat Shrink Joint -conventional and next generation. Raychem products offer excellent insulating and sealing performance with heat shrinkablematerials. These proven materials form the basis of straight and branch joints for voltages up to 1.1 kV and designed for solid dielectric cables (PVC/Rubber/XLPE).

1.1kV Heat Shrink Joint -conventional and next generation. Raychem products offer excellent insulating and sealing performance with heat shrinkablematerials. These proven materials form the basis of straight and branch joints for voltages up to 1.1 kV and designed for solid dielectric cables (PVC/Rubber/XLPE).

- Heat-shrink adhesive coated tubes and mastics

- Connector is suitable for wide range of cable

- Quick and easy installation

- Re-instatement and energisation immediately after installation

- Solutions for all cable constructions

1.1kV Heat Shrink Termination. Low voltage cable crutch is sealed by an adhesive lined heat-shrinkable breakout installed over cores and end of over sheath. The heat-shrinkable tubing seals between the cable lug and end of core insulation. All materials are resistant to UV-light and weathering

1.1kV Heat Shrink Termination. Low voltage cable crutch is sealed by an adhesive lined heat-shrinkable breakout installed over cores and end of over sheath. The heat-shrinkable tubing seals between the cable lug and end of core insulation. All materials are resistant to UV-light and weathering

- Heat Shrink technology

- Quick and easy Installation

- Solutions for all types of cable and constructions

- Hot melt adhesive coated cable breakout and sealing sleeves

- Fungi resistant

Medium Voltage Joints & Terminations

3.6 kV to 36 kV – Heat Shrink & Cold Applied

- Accessories are suitable for all types of cables having different screening and armour designs

- Conforms to various Standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2011

- Plug in GIS Terminations – EN 50180/181

- Next Gen Joints – Triple layer co-extruded single heat-shrinkable tubing incorporating precisely engineered impedance stress control. Supplied with Mechanical Connectors for a wide range of conductor sizes

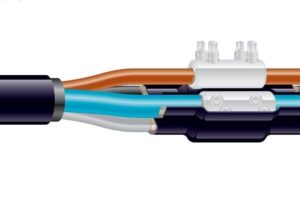

Medium Voltage Heat Shrink Joints-Conventional and next generation. Raychem developed highly specialized polymers for heat shrink joints suitable for plastic and paper cables upto 36 kV. For transition joints, a special oil barrier tubing is used to transform draining oil (MI) and non-draining oil (MIND) paper insulated cable into quasi-polymeric insulated cable with a radial field.

Medium Voltage Heat Shrink Joints-Conventional and next generation. Raychem developed highly specialized polymers for heat shrink joints suitable for plastic and paper cables upto 36 kV. For transition joints, a special oil barrier tubing is used to transform draining oil (MI) and non-draining oil (MIND) paper insulated cable into quasi-polymeric insulated cable with a radial field.

The conventional design developed in 1980 was based on multiple layer tubing concept providing insulation and stress functions. The latest developed heat shrink joint is a single tubing (triple layer co-extruded) of adequate thickness which provides insulation for a particular voltage range.

- Conventional Joints – Multi-layered heat-shrinkable tubing incorporating precisely engineered impedance stress control. EPKJ universal joints are suitable for a wide range of connectors and cable sizes with no limitations on shelf life

- Joints are suitable for all types of cables having different screening and armour designs

- Immediate energization after completion of joints

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

- Next Gen Joints – Triple layer co-extruded single heat-shrinkable tubing incorporating precisely engineered impedance stress control. MXSU joints are supplied with mechanical phase and screen connectors for a wide range of conductor sizes with no limitat

- Joints are suitable for all types of cables having different screening and armour designs

- Immediate energization after completion of joints

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

Medium Voltage Heat Shrink Terminations-Conventional and next generation.

Medium Voltage Heat Shrink Terminations-Conventional and next generation.

Conventional Terminations – Universal termination based on impedance (resistant) based stress control system upto 36 kV

- Immediate energization after completion of termination

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

- Next Gen Terminations – Universal termination based on unique Raychem zinc oxide stress control technology co extruded along with non-tracking tubing

- Immediate energization after completion of termination

- Conforms to various national and international standards like CENELEC HD.629.1.S2:2006, IEC 60502-4, IEEE 48 and IS 13573-2

Medium Voltage screened separable connectors for switchgears. Raychem developed screened separable connectors for switchgears which are compact and space saving, having high degree of reliability and safety. These terminations are designed, developed, and tested upto 36 kV for almost all sizes of cables. Switchgear terminations are either OUTER CONE type (suitable for bushings as per EN 50181 for Type A (250 Amps), B (400 Amps), C (630/800 & 1250 Amps)) or INNER CONE type Size 2 (800 Amps) and Size 3 (1250 Amps). Screened separable connectors conform to IEEE bushings and terminations to CENELEC HD 629.1 and IS 13573-2 standards.

Medium Voltage screened separable connectors for switchgears. Raychem developed screened separable connectors for switchgears which are compact and space saving, having high degree of reliability and safety. These terminations are designed, developed, and tested upto 36 kV for almost all sizes of cables. Switchgear terminations are either OUTER CONE type (suitable for bushings as per EN 50181 for Type A (250 Amps), B (400 Amps), C (630/800 & 1250 Amps)) or INNER CONE type Size 2 (800 Amps) and Size 3 (1250 Amps). Screened separable connectors conform to IEEE bushings and terminations to CENELEC HD 629.1 and IS 13573-2 standards.

- Outer Cone – Angled prefabricated shielded adapter made of silicone rubber or EPDM, does not require heat during installation

- Integrated stress control Separate termination not required Stress Control – Geometrical, Refractive or Impedance type

- Test point for capacitive voltage measurement

- Mechanical lugs included

- Inner Cone – Shielded inline connection for gas insulated switchgears up to 36 kV

- Plug-in termination having geometrical stress control system is metal-enclosed, hermetically insulated and suitable for submersion or outdoor use

- Voltage detector facility available upon request

- Wedge Connector included

High Voltage Joints & Terminations

52 kV & 72 kV – Heat Shrink

- Compact and modular design

- Quick and easy to install

- No special or expensive tools required

- Lightweight components

- Reduced waste for disposal

- Wide installed base across the country

Heat Shrink High Voltage Joints

HV Heat Shrink Joint.Polymeric insulated cables of various designs can be adapted with respect to shielding and metal sheath. Raychem heat shrink accessories have been used by utilities and industrial companies around the world for over 40 years. The ongoing field experience makes Raychem a leader in materials science and technology for high voltage applications. The materials used in TE Connectivity Raychem cable accessories are extensively optimized with respect to product design, function, manufacturing and expected service environment.

HV Heat Shrink Joint.Polymeric insulated cables of various designs can be adapted with respect to shielding and metal sheath. Raychem heat shrink accessories have been used by utilities and industrial companies around the world for over 40 years. The ongoing field experience makes Raychem a leader in materials science and technology for high voltage applications. The materials used in TE Connectivity Raychem cable accessories are extensively optimized with respect to product design, function, manufacturing and expected service environment.

Heat Shrink High Voltage Terminations

HV Heat Shrink Termination. Heat shrink high voltage terminations upto 72 kV are in service for over 40 years. They are suitable for installation in all climates, environments and polluted areas. Heat shrink high voltage termination comply to IEC 60840.

Extra High Voltage Joints & Terminations

72 kV to 245 kV – Pre Moulded

- Fluid filled Composite Insulator Termination – leak proof and light weight composite housing

- Dry Flexible Self-Support Termination

- Dry compact GIS/Transformer termination

- Complies with IEC 62271-209 standard

- Type Tested as per IEC 60840

- Special Joints for Two Dissimilar Cables

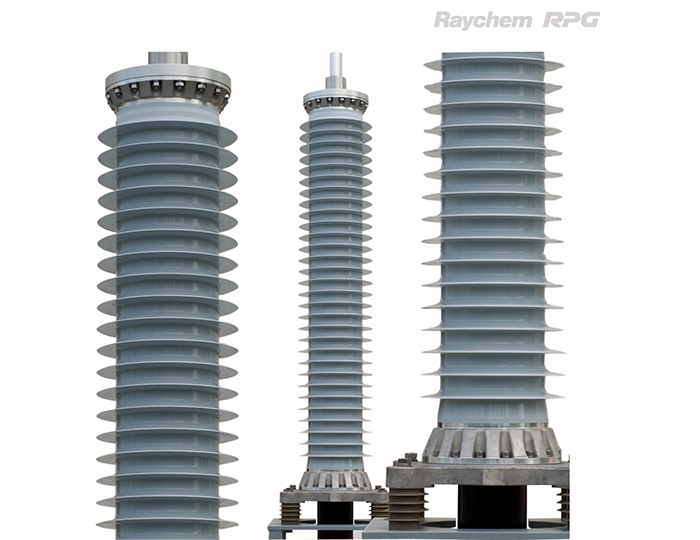

EHV Outdoor Terminations

High Voltage Outdoor Terminations upto 245 kV – Dry type and Fluid filled type with Composite insulator including link boxes. Composite terminations for voltage classes up to 245 kV operate under severe environmental conditions. Composite housings with creepage lengths up to 31 mm/kV are available for the most common and extremely pollution levels, according to IEC 60815 standard.

High Voltage Outdoor Terminations upto 245 kV – Dry type and Fluid filled type with Composite insulator including link boxes. Composite terminations for voltage classes up to 245 kV operate under severe environmental conditions. Composite housings with creepage lengths up to 31 mm/kV are available for the most common and extremely pollution levels, according to IEC 60815 standard.

- Fluid filled Composite Insulator Termination – leak proof and light weight composite housing

- Fittings made of corrosion-resistant alloy

- Prefabricated and factory-tested silicone-rubber stress cone

- Torque-controlled shear head mechanical connector

- Insulating-oil filling without preheating

- No special tools required for installation

- Insulated base plate for sheath sectionalization

- Type tested according to IEC 60840 and IEC 62067 standards

- Dry and Dry Flexible Self-Support Termination – Dry interface, no oil-filling

- Self-supporting

- Prefabricated and factory tested silicone-rubber stress cone

- Torque-controlled shear head mechanical connector/compression connector

- Fast and simple installation combining GIS plug-in technology with polymeric insulators

- No special tools required for installation

- Insulated base plate gland for sheath sectionalization

- Type tested according to IEC 6084

GIS/Equipment Terminations

The dry compact GIS/Transformer termination for voltage classes up to 245 kV is designed to be installed in cable entry housings of gas-insulated switchgear (GIS)/Transformer.

The dry compact GIS/Transformer termination for voltage classes up to 245 kV is designed to be installed in cable entry housings of gas-insulated switchgear (GIS)/Transformer.

- Complies with IEC 62271-209 standard, which essentially specifies interfaces between termination and switchgear

- Adapters available to match dimensions of wet (oil-filled) type terminations, as specified in IEC 60859

- Insulator can be installed by GIS / transformer manufacturer at factory, saving installation time on-site and reducing risk of contamination of cable entry housing

- No special tools required for installation

- Easily separable, consists of a plug-in part and epoxy resin insulator

- Transformer Terminations comply to dimensions as per EN50299 Standard

Pre Moulded EHV Joints

Pre moulded design of Joints for voltages upto 245 kV. Available in Single/One piece design upto 245 kV and Three piece design for 145 kV. The silicone rubber joint body with integrated geometrical stress control, provides proven electrical functions. Joint components combine electrical performance, stress control and moisture sealing to provide important functions required for high voltage equipment.

Pre moulded design of Joints for voltages upto 245 kV. Available in Single/One piece design upto 245 kV and Three piece design for 145 kV. The silicone rubber joint body with integrated geometrical stress control, provides proven electrical functions. Joint components combine electrical performance, stress control and moisture sealing to provide important functions required for high voltage equipment.

- Single Piece – Premoulded one-piece joint body upto 245 kV

- Torque-controlled connector

- Joint fits on all polymeric cable constructions

- Proven shield continuity concept

- Factory tested silicone rubber body

- Special silicone rubber provides perfect compression force for optimized electrical performance

- Simple assembly

- Choice of outer sealing and protection system

- No tension set of joint body

- Moulded/Painted outer conductive screen

- Geometrical electrical stress control by moulded conductive deflectors

- Type tested according to IEC 60840, IEC 62067 standards

- Three Piece – Premoulded three-piece joint design upto 145 kV

- Torque-controlled connector

- Joint fits on all polymeric cable constructions

- Proven shield continuity concept

- Factory tested silicone rubber body

- Special silicone rubber provides perfect compression force for optimized electrical performance

- Short cut-back dimensions, cable size transition possible

- No special tools required for installation

- No tension set of joint body

- Moulded outer conductive screen

- Geometrical electrical stress control by moulded conductive deflectors

- Type Tested as per IEC: 60840

Work Gallery

Our Customers